Email:zarya@z-keytech.com

Tel: 86-15258835100

What is Metal Casting?

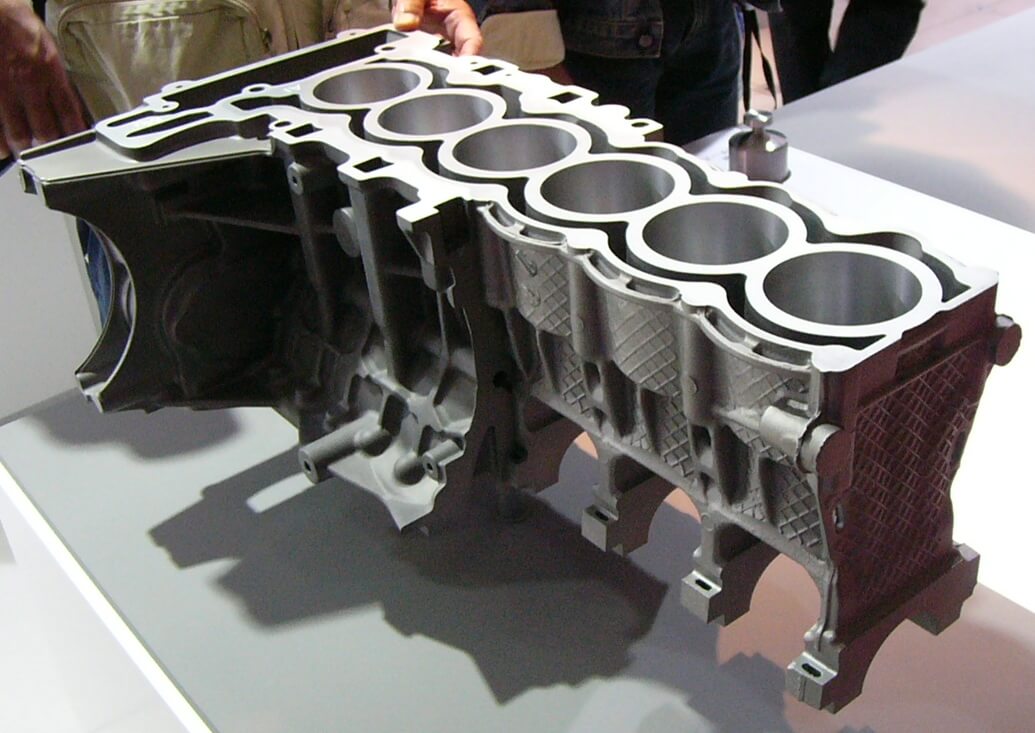

Metal Casting is defined as the process in which molten metal is poured into a mould that contains a hollow cavity of a desired geometrical shape and allowed to cool down to form a solidified part.

It is used to make complex and large parts with mold, which would have been difficult or expensive to manufacture using other manufacturing processes.

The inside of the mold is designed with a negative impression of the part being made, so when the molten metal cools and solidifies within the mold, it takes the shape of the final part. The finished part can then be removed from the mold.

Z-Key Tech Metal Casting

Z-Key Tech Metal Casting services include below methods:

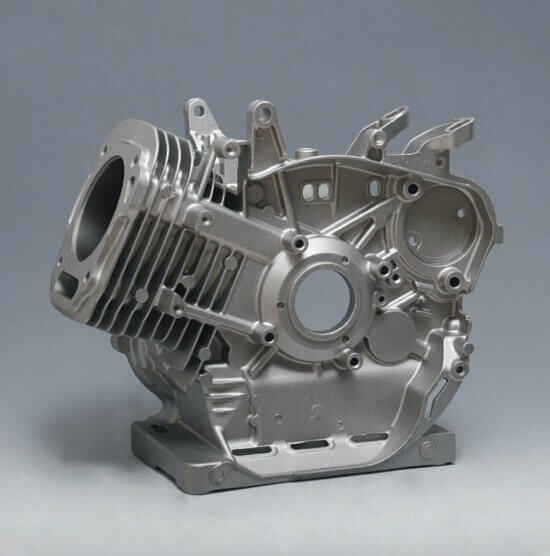

Die Casting

Die Casting is one of the most important types of Metal Casting for intricate and detailed parts, it uses two reusable tool steel dies as tooling. The process is similar to plastic injection molding: the molten material is forced into the cavity at high pressure. The cost of creating custom dies is quite high, which makes the process more common in mass production because the dies can be used many times. Normally, Die Castings tend to have an excellent surface finish.

Gravity Casting

Gravity Casting is also a way of casting metal using a reusable metal mold. However, gravity casting relies upon gravitational forces to move liquid metal through the mold, top to bottom, rather than pressure. Molds must be preheated before the first casting and are often made from cast iron due to its low thermal fatigue.Sand Casting

Sand Casting is a simple method of casting metal and is more affordable than alternative techniques. It uses sand (mixed with a bonding material like clay) as a mold material, and the molds are capable of withstanding high heat. In the sand casting process, a pattern is immersed in sand contained within a special box called a flask. By compacting the sand around the pattern, a mold can be made into which molten metal can be poured.

Advantages of Metal Casting

Produce huge/heavy/complex parts in one piece.

Excellent bearing qualities.

Material versatility, almost all the metal can be cast.

Features like internal cavities or hollow sections can be easily achieved

Suitable for mass production