Email:zarya@z-keytech.com

Tel: 86-15258835100

What is Rapid Tooling?

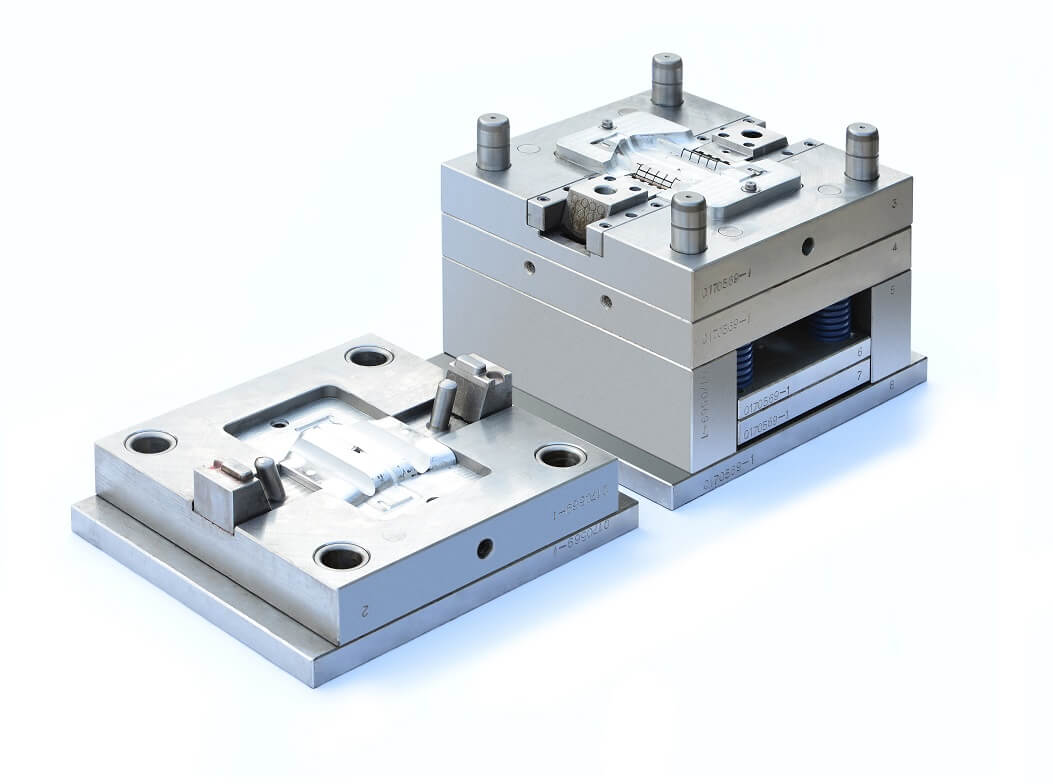

Rapid tooling, also known as prototype tooling, soft tooling and bridge tooling, is a fast and cost-efficient way to carry out low-volume injection molding for a variety of types of plastic parts.

Once the aluminum or steel mold has been created with the rapid tooling process, it can be utilized as part of a molding process to create multiple copies of a part.

Rapid tooling is therefore used to create moldings for rapid prototyping needs in a shortened timeframe, or to bridge the gap before high-volume production.

Z-Key Tech Rapid Tooling

Z-Key Tech Rapid Tooling services include below methods:

Rapid Injection Molding

Injection molding is the most common manufacturing process for making plastic parts. It refers to the method that under a certain temperature, the plastic material completely melted by screw stirring is injected into the mold cavity with high pressure, and then cooled and solidified to obtain the injection product. This method is really cost effective and it's suitable for the mass production.

Rapid Tooling

Rapid Tooling is one of the best methods for fulfilling small batch orders meant for use in marketing samples, product evaluations, and process design. You can use Aluminum or Steel mold according to the quantity of your products. Create Rapid Tooling to conduct trial production before mass production is a very useful step for design optimization, functional testing, and pre-production verification.Advantages of Rapid Tooling

Good dimensional accuracy.

Excellent repeatability and flexibility.

Minimize the material waste.

Great surface finish.

High productivity, easy to realize automatic operation.