What is CNC Machining?

Computer Numerical Control (CNC) machining represent a manufacturing process used to control a wide range of tasks using pre-programmed computer software to dictate the movement of factory tools and machinery.

The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers.

With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts. In today’s CNC protocols, the production of parts via pre-programmed software is mostly automated. The dimensions for a given part are set into place with computer-aided design (CAD) software and then converted into an actual finished product with computer-aided manufacturing (CAM) software.

Z-Key Tech CNC Machining

Z-Key Tech CNC Machining services include below methods:

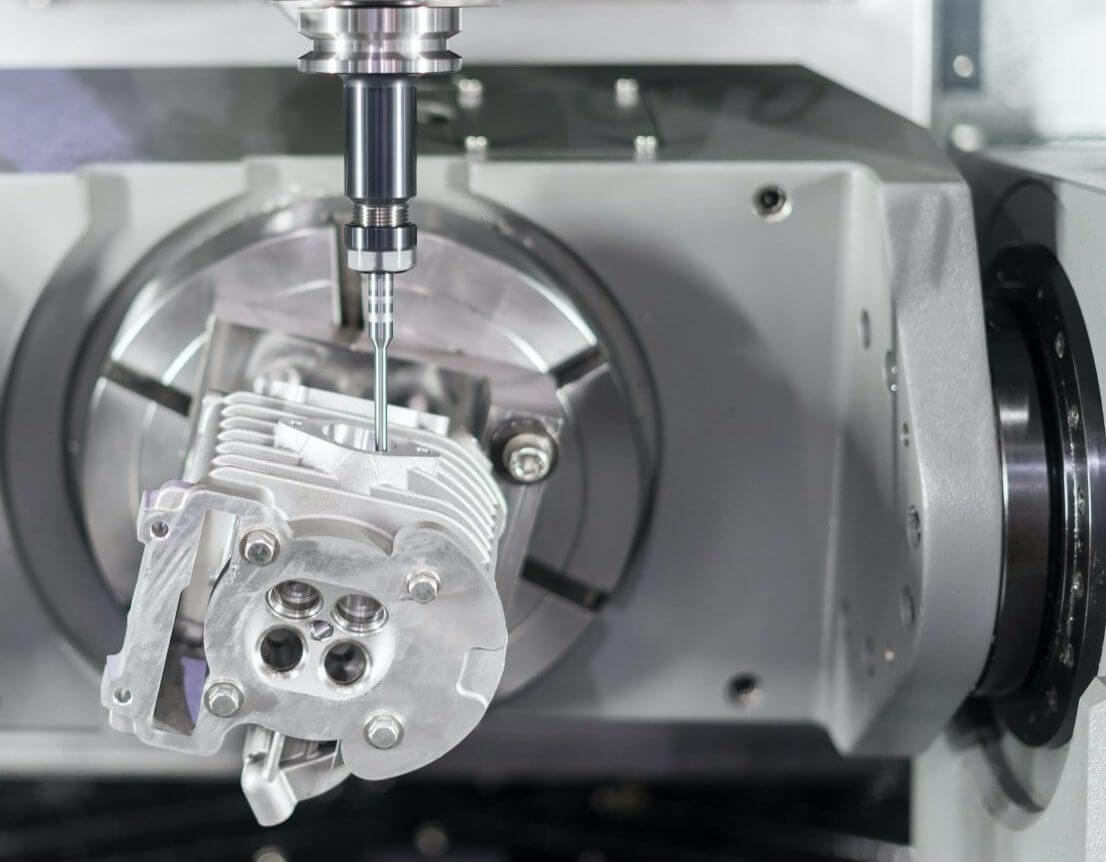

CNC Precision Machining

CNC Precision Machining uses presicion CNC machining to manufacture part with strict design specification, critical tolerance and high-demand surfaces. Using 3 to 5 axis CNC machines and professsional experiences, we offers high quality precised complex parts, such as automotive engine, housing, hubs etc.

CNC Milling

CNC Milling is a subtractive form of manufacturing that can be used for cutting and machining operations of various plastic and metal materials. Milling is the most versatile CNC Machining process with high adaptability and flexibility. It is suitable for any industry that requires precision components and also an ideal way for making molds. CNC milled parts can be machined in multiple processes after one set-up; 5-axis CNC Milling can be machined on multiple surfaces at one timeCNC Turning

CNC Turing is the process of remove material from a rotating workpiece using the linear path of tools on a CNC lathe or turning center. Multi-axis CNC Turning centers allow multiple processes and multi-step machining operations on a single machine, making them a cost-effective option for complex geometries.